Industry knowledge

What are some of the safety considerations that must be taken into account when working with Boring Cutters?

Personal Protective Equipment (PPE): Always wear the appropriate PPE when working with Boring Cutters, including safety glasses or face shields, hearing protection, and protective gloves. Loose clothing and jewelry should be removed or secured to prevent entanglement with the cutter.

Machine Guarding: Ensure that the machine is properly guarded to prevent accidental contact with the Boring Cutter while it is in operation. Guards should be in place to prevent access to the rotating parts of the machine.

Chip Control: Boring Cutters generate chips and debris that can be sharp and hot, posing a hazard to operators. Proper chip control methods, such as using coolant or lubrication, and the appropriate chip management system, such as chip conveyor, should be implemented.

Cutting Parameters: Use appropriate cutting parameters for the material being machined and the specific Boring Cutter being used to prevent tool breakage or other issues that can lead to accidents.

Proper Training: Ensure that operators are properly trained and familiar with the machine tooling and Boring Cutter before operating it.

Handling and Storage: Boring Cutters should be handled and stored with care to prevent damage, which could lead to breakage during operation.

Regular Maintenance: Regular maintenance of the machine tooling and Boring Cutter can help prevent accidents caused by worn or damaged parts.

What are the most common applications for Boring Cutters in the machining industry?What factors should be considered when selecting a Boring Cutter for a specific machining operation?

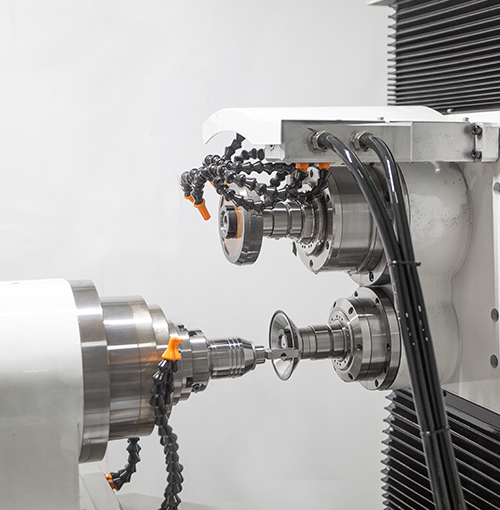

The most common applications for Boring Cutters in the machining industry include creating precision bores in metal or other materials, such as engine blocks, cylinders, and bearing housings. Boring Cutters are also commonly used for producing holes that are deeper than they are wide, such as those required for gun barrels and pipes.

When selecting a Boring Cutter for a specific machining operation, several factors should be considered, including the material being machined, the required hole diameter and depth, the desired surface finish, and the machine's spindle speed and horsepower. Other factors may include the available tooling and the specific geometry of the part being machined. The choice of Boring Cutter will also depend on the type of machine being used, such as a horizontal or vertical boring mill, and the type of cutting tools available, such as single-point or multi-point cutters.

The rigidity of the machine and the workpiece setup are also critical considerations when selecting a Boring Cutter, as they can significantly impact the cutter's performance and tool life. The Boring Cutter's shape and size must be chosen to match the required hole diameter and depth, and the tool's cutting edge geometry and material must be appropriate for the workpiece material and machining conditions.

Other factors that may influence the selection of a Boring Cutter include the desired cycle time, the availability of coolant or lubrication, and the operator's experience and expertise with the tool. Ultimately, selecting the right Boring Cutter for a specific machining operation requires careful consideration of all these factors to ensure optimal performance and efficiency.

What materials are best suited for Boring Cutters, and how do they affect the cutting process?How can Boring Cutter maintenance be optimized to extend their lifespan and reduce downtime?

Boring Cutters are commonly made from high-speed steel, carbide, or diamond. High-speed steel cutters are less expensive and can be resharpened, making them a good choice for low- to medium-volume machining applications. Carbide cutters, on the other hand, are more wear-resistant and can provide longer tool life in high-volume production environments. Diamond cutters are the most wear-resistant and can provide exceptionally long tool life when machining hard, abrasive materials such as ceramics and composites.

The material being machined also affects the cutting process. Softer materials such as aluminum and brass can be machined with less wear on the cutter, while harder materials like stainless steel and titanium require more wear-resistant cutters and may generate higher temperatures during cutting. Different cutting speeds, feeds, and coolant or lubrication strategies may also be required for different materials.

Boring Cutter maintenance can be optimized in several ways to extend their lifespan and reduce downtime. First, it's important to choose the right coolant or lubrication for the cutting operation to reduce wear and extend tool life. Regular cleaning of the Boring Cutter and machine tooling can also help prevent buildup of chips and debris that can cause premature wear or damage. Resharpening or replacing Boring Cutters when they become dull or damaged can help maintain cutting performance and reduce the risk of tool breakage or other problems.

It's also essential to monitor Boring Cutter performance regularly, such as checking for signs of wear or damage, and adjusting cutting parameters as necessary to optimize cutting performance. Additionally, proper storage and handling of Boring Cutters can help prevent damage during transport and storage. By implementing a regular maintenance program that addresses all of these factors, the lifespan of Boring Cutters can be extended, reducing downtime and improving machining efficiency.